|

|

Modbus Master Protocol Configuration Section

This information applies to latest revision.

This driver is made by the two modules: modbus_driver.dll and modbus_master.exe

This driver maps modbus data formats to IEC data types using the following mapping:

| Register type | Function | Modbus_type | iec_type | offset |

|---|

| Holding Register, Analog Input, Read | 3 | VT_I4 | M_IT_TB_1 | 40001 |

| Holding Register, Analog Input, Read | 3 | VT_UI4 | M_ME_TO_1 | 40001 |

| Holding Register, Analog Input, Read | 3 | VT_R4 | M_ME_TF_1 | 40001 |

| Holding Register, Analog Input, Read | 3 | VT_R4SWAP | M_ME_TF_1 | 40001 |

| Holding Register, Analog Input, Read | 3 | VT_I2 | M_ME_TE_1 | 40001 |

| Holding Register, Analog Input, Read | 3 | VT_UI2 | M_ME_TQ_1 | 40001 |

| Holding Register, Digital Input, Read | 3 | VT_DP | M_DP_TB_1 | 40001 |

| Holding Register, Analog Output, Write | 16 | VT_I4 | C_BO_TA_1 | 40001 |

| Holding Register, Analog Output, Write | 16 | VT_R4 | C_SE_TC_1 | 40001 |

| Holding Register, Analog Output, Write | 16 | VT_R4SWAP | C_SE_TC_1 | 40001 |

| Holding Register, Analog Output, Write | 16 | VT_I2 | C_SE_TB_1 | 40001 |

| Input Register, Analog Input, Read Only | 4 | VT_I4 | M_IT_TB_1 | 30001 |

| Input Register, Analog Input, Read Only | 4 | VT_UI4 | M_ME_TO_1 | 30001 |

| Input Register, Analog Input, Read Only | 4 | VT_R4 | M_ME_TF_1 | 30001 |

| Input Register, Analog Input, Read Only | 4 | VT_R4SWAP | M_ME_TF_1 | 30001 |

| Input Register, Analog Input, Read Only | 4 | VT_I2 | M_ME_TE_1 | 30001 |

| Input Register, Analog Input, Read Only | 4 | VT_UI2 | M_ME_TQ_1 | 30001 |

| Coil, Digital Input, Read | 1 | VT_BOOL | M_SP_TB_1 | 00001 |

| Coil, Digital Output, Write | 5 | VT_BOOL | C_SC_TA_1 | 00001 |

| Input Status or Discrete Input, Digital Input, Read Only | 2 | VT_BOOL | M_SP_TB_1 | 10001 |

where

VT_I4 is a 32 bits signed integer

VT_UI4 is a 32 bits unsigned integer

VT_R4 is 32 bits float

VT_R4SWAP is 32 bits float with words swapped

VT_I2 is a 16 bits signed integer

VT_UI2 is a 16 bits unsigned integer

VT_BOOL is a bit

Step 1:

Creation of modbus protocol configuration database

Go to C:\scada\bin and run protocol_configurator.exe

For each device create a modbus database and a SCADA Unit.

A SCADA Unit corresponds to a SCADA line.

Example: For the device connected on line 1 create the database named modbus_database1.db and save it in C:\scada\project

For the device connected on line 2 create the database named modbus_database2.db and so on

Line 1 corresponds with the first Unit created, line 2 with the second Unit created and so on

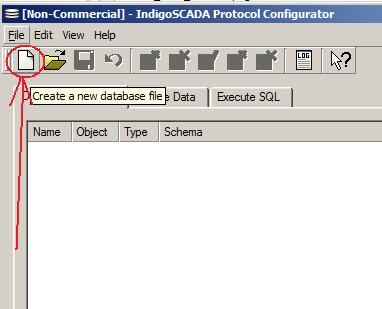

Create modbus_database1.db

|

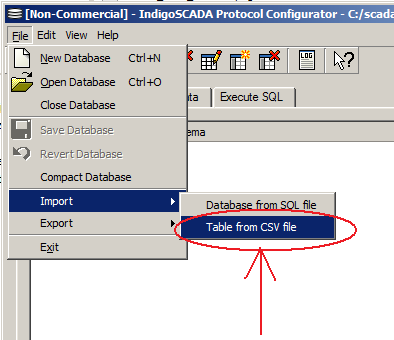

Select the import table menu. Import modbus_table.csv

|

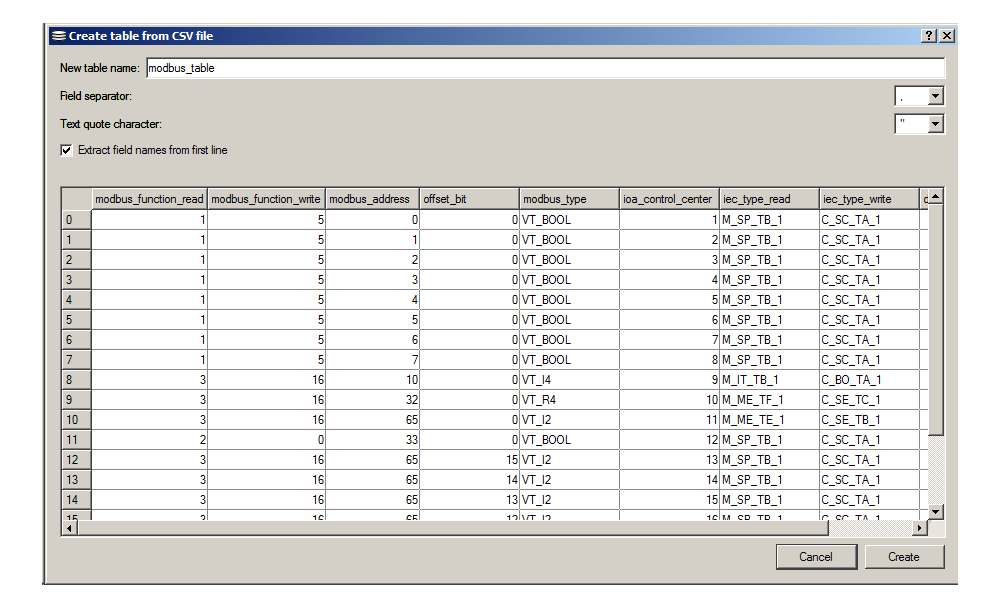

Imported modbus_table.csv

|

Step 2:

Creation of the new SCADA points

1 - Select the menu: Configure\Configure Units

2 - Press button New

3 - Fill in the edit field Name: MDB

4 - Select Type modbus_driver, flag Unit Enabled and press Configure button

5 - Fill in the Modbus slave IP address, TCP port, number of points and Update Intervall in milliseconds for MODBUS TCP.

6 - Fill in the serial device, baud, data bits, stop bit, parity, number of points and Update Intervall in milliseconds for MODBUS RTU.

7 - Press button Apply and wait that the Apply button returns active and then press Exit

8 - Restart monitor.exe

9 - Monitored sample points are now visible

Step 3:

Configure each sample point

8 - Select the menu: Configure\Configure Sample Points

9 - Set Comment, Type, Units and the limits of each new point. Press button Apply

- Set type M_SP_TB_1 for digital point

- Set type M_ME_TC_1 for analog point

10 - Open HMI designer, select the widget and edit the maxValue and min Value

11 - The corresponding HMI object, here MDBPoint11, get the new maxValue and min Value.

Step 4:

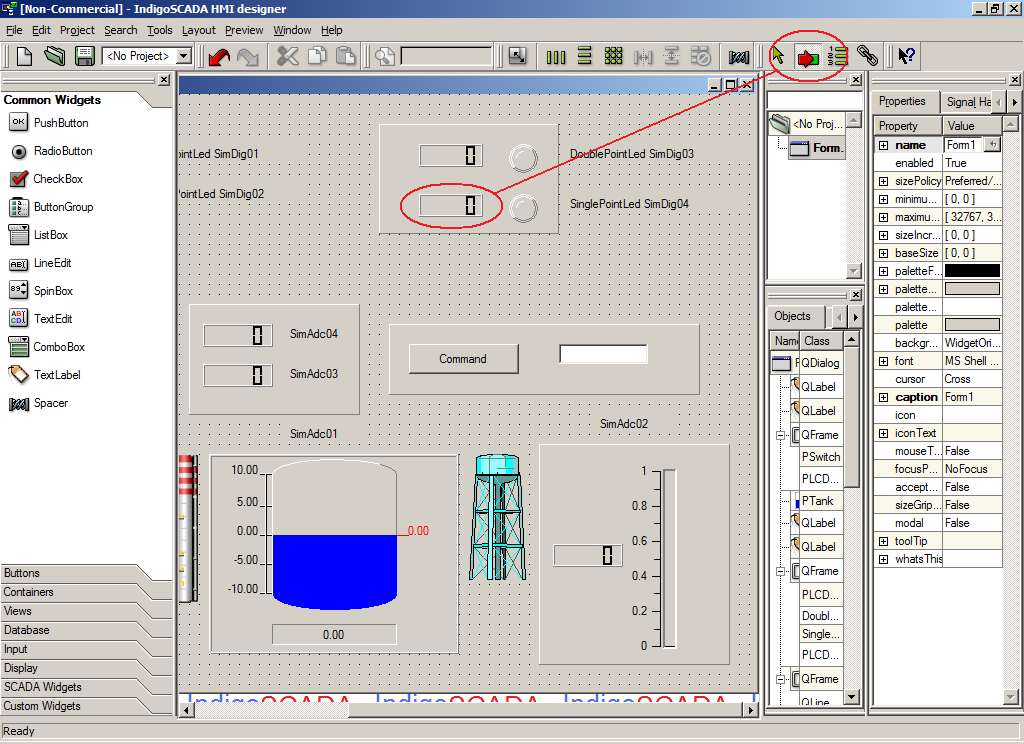

HMI configuration with HMI designer

10 - Run the process C:\scada\bin\hmi_designer.exe

11 - Create from scratch your HMI (dialog) and save it as hmi0.ui in C:\scada\project

12 - Use the following widget classes

| Widget | Class

|

| SINGLE POINT LED | PSinglePointLed

|

| DOUBLE POINT LED | PDoublePointLed |

| SINGLE POINT LED | SinglePointLed |

| DOUBLE POINT LED | DoublePointLed

|

| SWITCH | PSwitch

|

| THERMOMETER | QwtThermo

|

| LCD NUMBER | PLCDNumber |

| COMMAND BUTTON | QPushButton |

| TANK | PTank |

| THERMOMETER | PThermometer |

| EDIT FIELD | QLineEdit |

| BREAKER | Breaker |

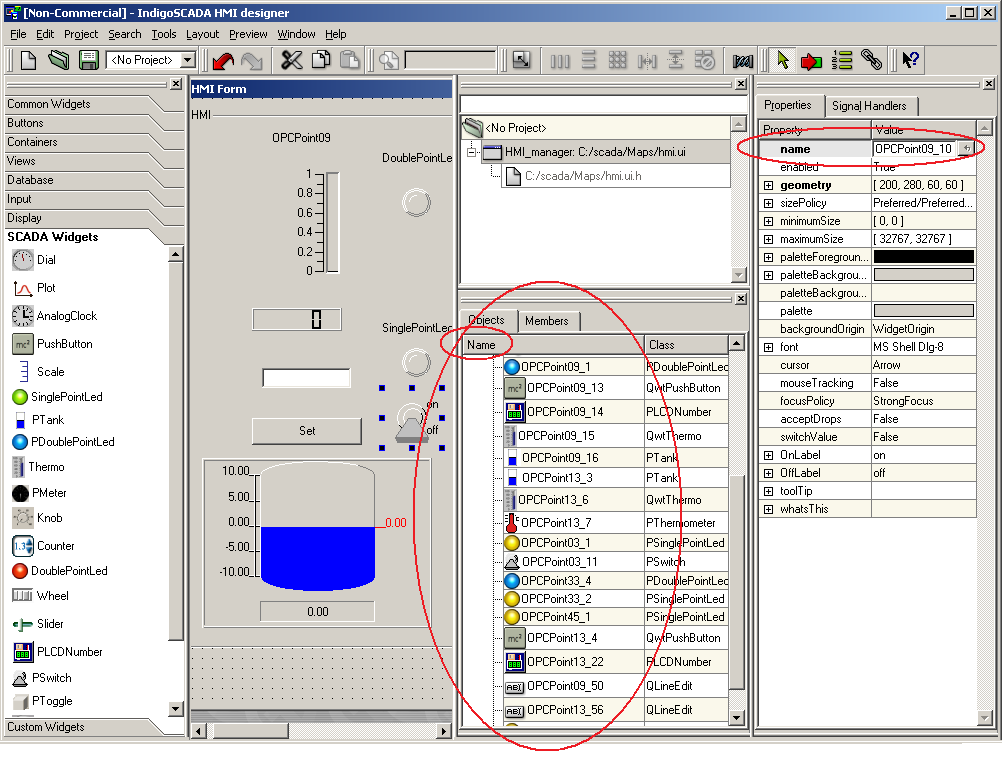

13 - Widget names MUST contain the underscore _ as separator between sample point SCADA name and widget ID

For example the widget with SCADA name MDBSample09 and ID 1 has full name: MDBSample09_1

Please see next image 1

1

|

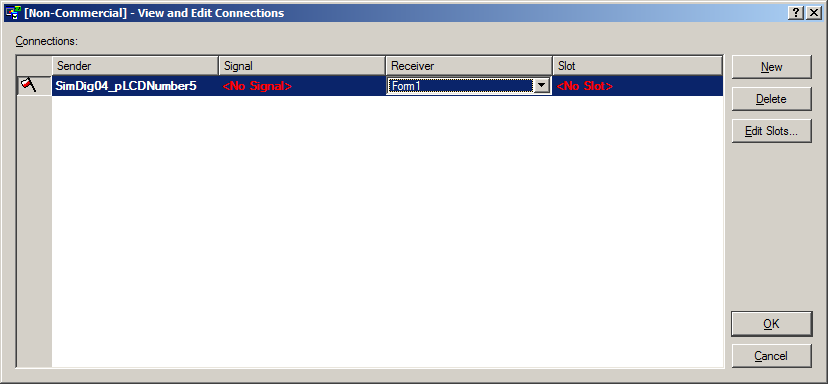

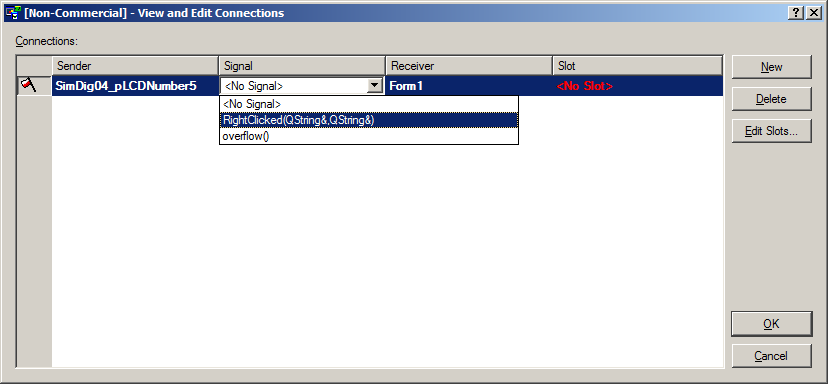

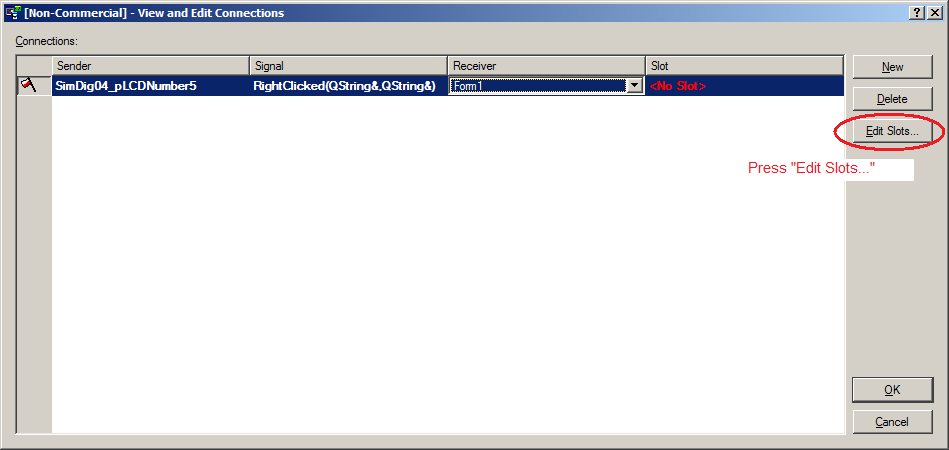

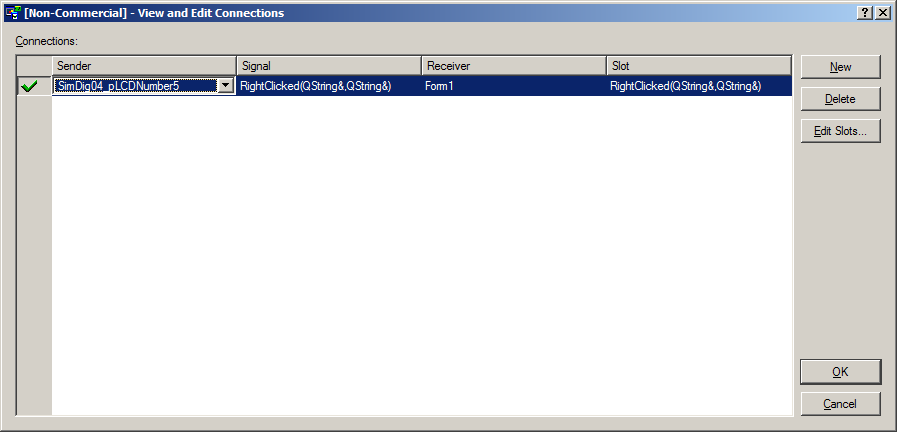

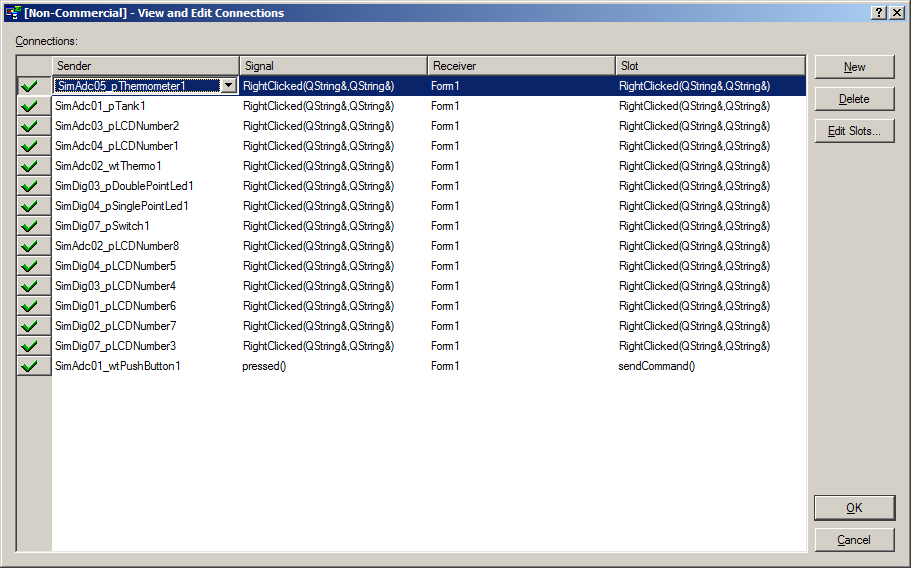

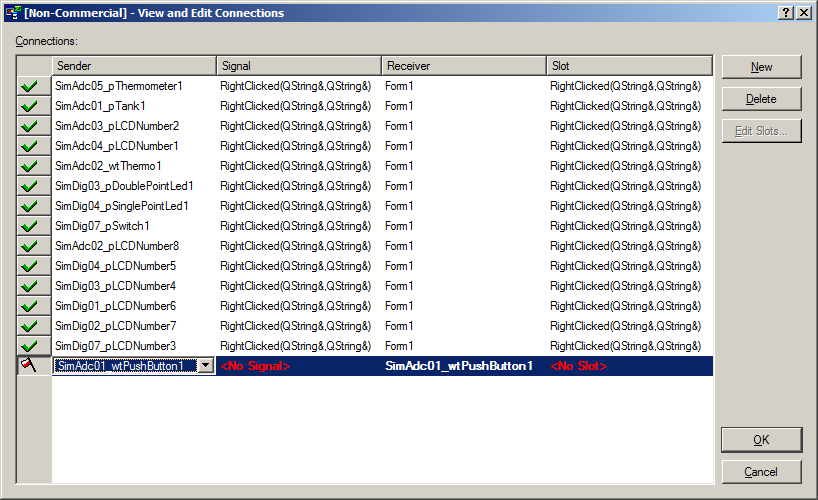

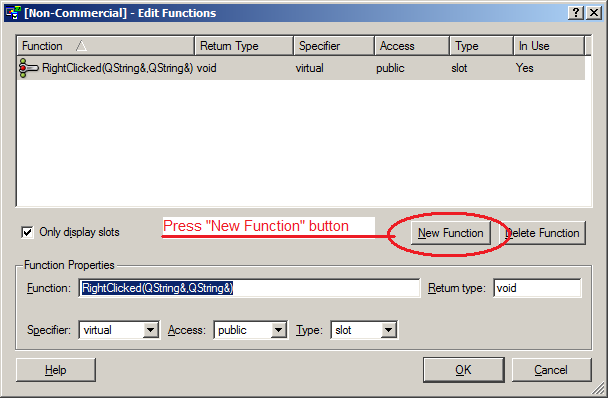

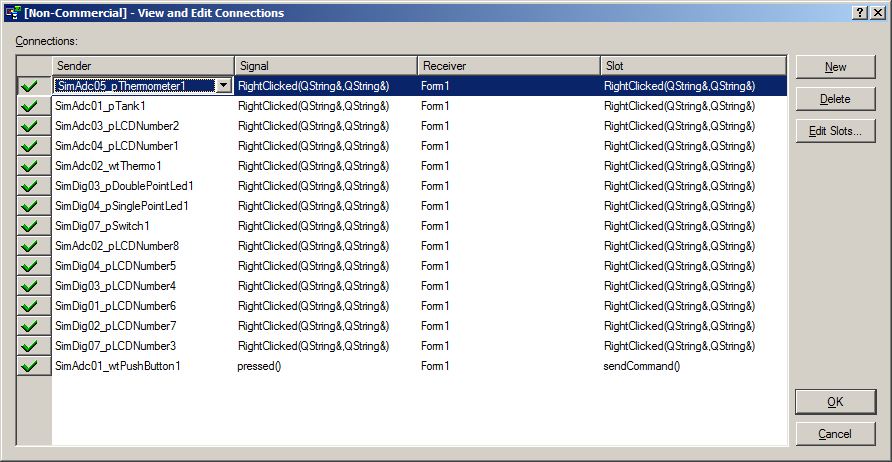

14 - To enable the inspect popup window, please follow the procedure:

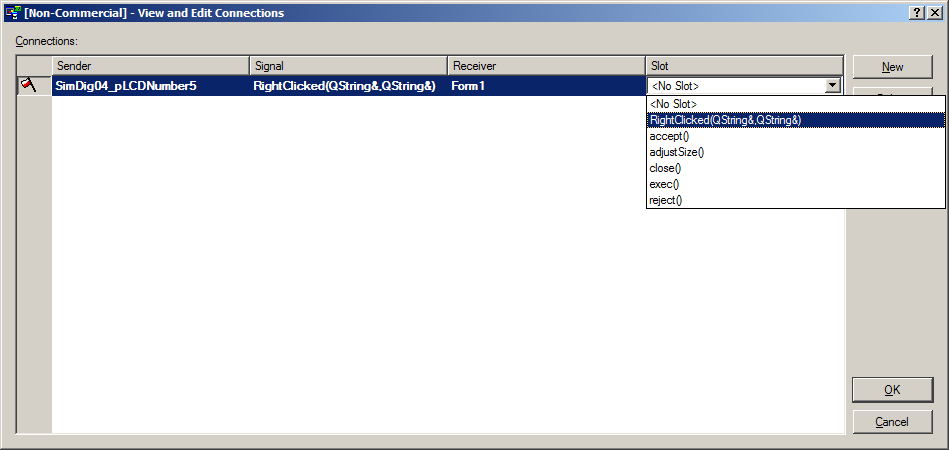

You have to connect the signals RightClicked(QString&,QString&) of the widgets with the slot RightClicked(QString&,QString&) of the HMI dialog (here Form1)

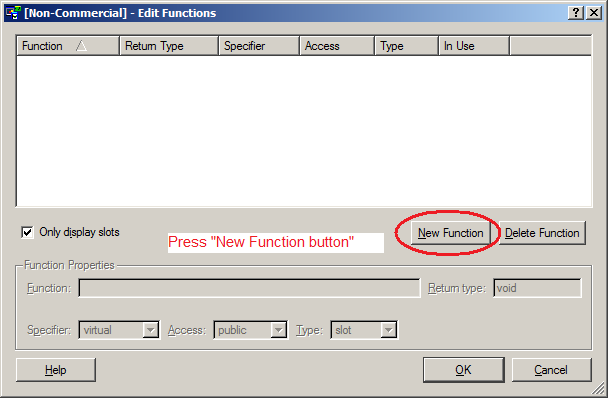

Step 1

|

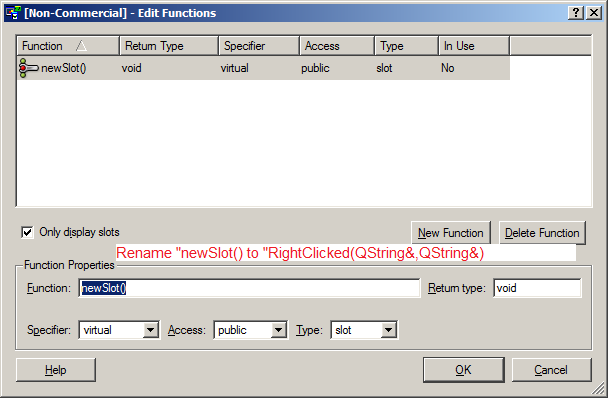

Step 2

|

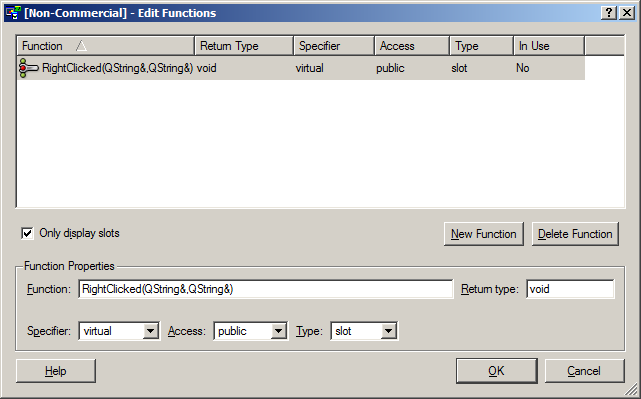

Step 3

|

Step 4

|

Step 5

|

Step 6

|

Step 7

|

Step 8

|

Step 9

|

Final result

|

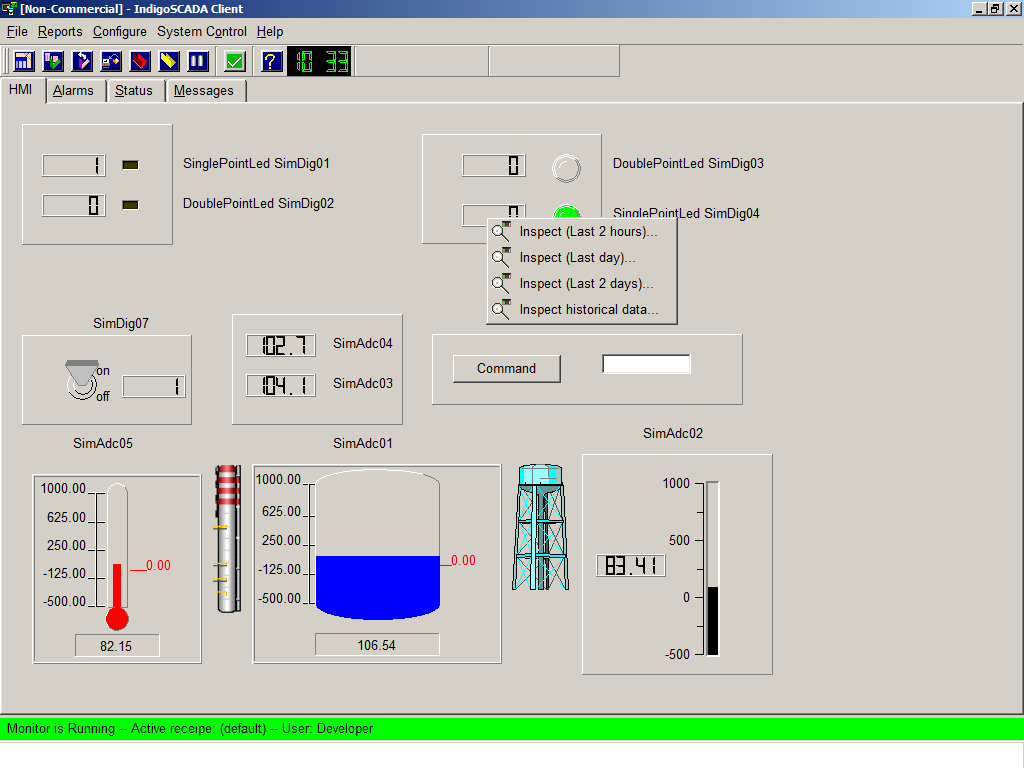

Working popup on HMI

|

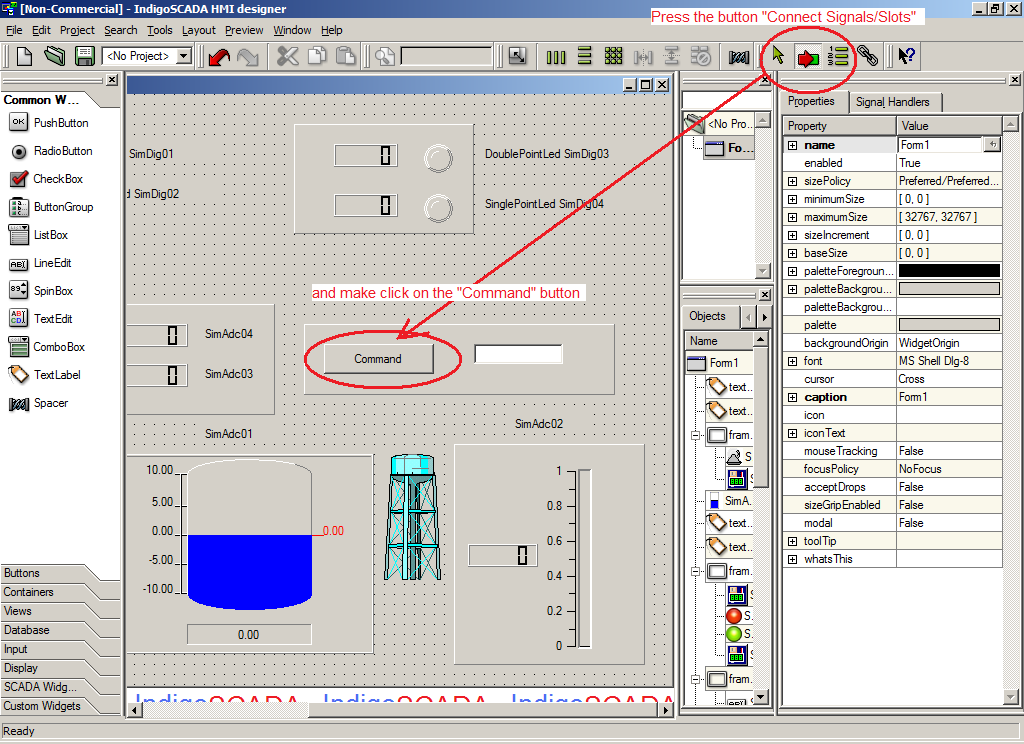

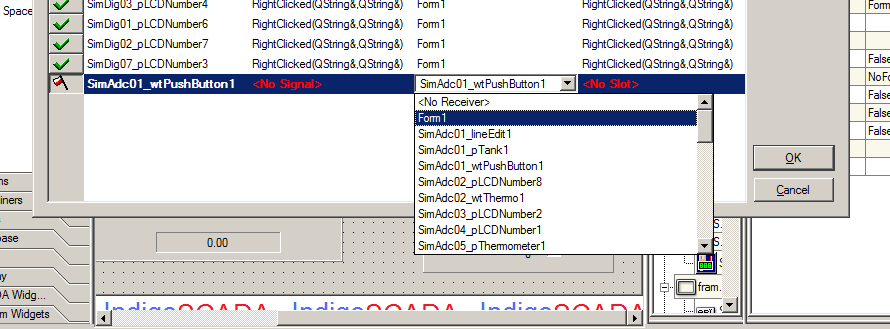

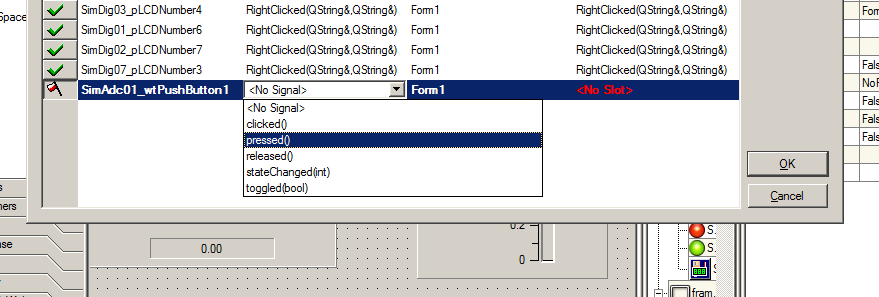

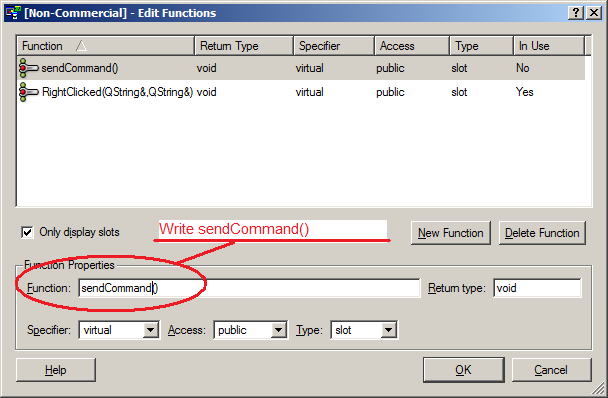

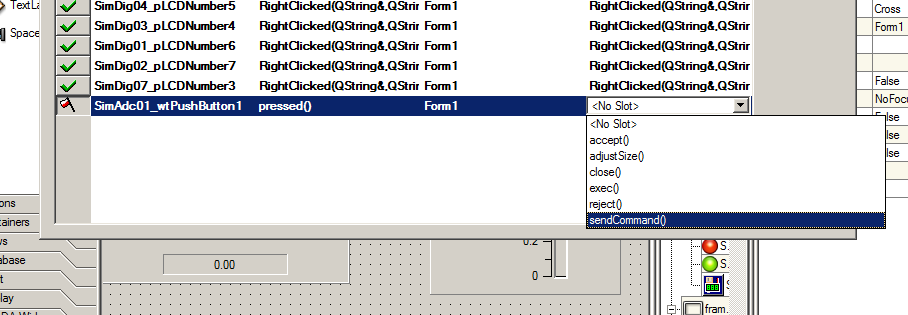

15 - To enable commands, please follow the procedure:

Step 1

|

Step 2

|

Step 3

|

Step 4

|

Step 5

|

Step 6

|

Step 7

|

Step 8

|

Step 9

|

Swap of word in float number

Test with float NOT swapped

slave_id = 1

modbus_function_read = 3

modbus_function_write = 16

modbus_address = 0

modbus_type = VT_R4

ioa_control_center = 10

deadband = 0

[00][01][00][00][00][06][01][03][00][00][00][02]

Waiting for a confirmation...

<00><01><00><00><00><07><01><03><04><41>

modbus_read_registers: Get float: -1868585380923580700000000000000000.000000

The next test is with SWAP of float WORD

slave_id = 1

modbus_function_read = 3

modbus_function_write = 16

modbus_address = 0

modbus_type = VT_R4SWAP

ioa_control_center = 10

deadband = 0

[00][01][00][00][00][06][01][03][00][00][00][02]

Waiting for a confirmation...

<00><01><00><00><00><07><01><03><04><41>

modbus_read_registers: Get float: 23.370468

- FloatConverter IEEE754 - FloatConverter IEEE754

|

|

|